9004-35-7

- Product Name:Cellulose acetate

- Molecular Formula:[C6H7O2(OH)3-m(OOCCH3)m],m=0~3

- Purity:99%

- Molecular Weight:0

Product Details;

CasNo: 9004-35-7

Molecular Formula: [C6H7O2(OH)3-m(OOCCH3)m],m=0~3

Appearance: white powder

Buy High Grade Top Purity 99% Cellulose acetate 9004-35-7 Safe Shipping

- Molecular Formula:[C6H7O2(OH)3-m(OOCCH3)m],m=0~3

- Molecular Weight:0

- Appearance/Colour:white powder

- Melting Point:230-300℃

- Refractive Index:n20/D 1.475(lit.)

- Boiling Point:210 °C

- Flash Point:304 C (closed cup)

- PSA:63.22000

- Density:1.3g/mLat25°C(lit.)

- LogP:-0.09540

Cellulose acetate (Cas 9004-35-7) Usage

Cellulose acetate is a synthetic compound derived from cellulose, a plant substance, making it a nontoxic, nonirritant, and biodegradable material. Known for its heat resistance and low hygroscopicity, cellulose acetate is produced through the chemical modification of cellulose obtained from nonedible plant parts like wood fibers and cotton. The cellulose is sourced from sustainably managed forests or cotton linters and combined with acetic acid, a key component of vinegar.

One of its primary applications is as a forming substance for acetate fiber, which is further processed into textile fibers such as acetate rayon, acetate, or triacetate. Cellulose acetate is also utilized in certain medications, including Allegra, Azulfidine EN-tabs, and Glipizide Extended-Release.

9004-35-7 Relevant articles

Biodegradable Plastics Based on Cellulose Acetate

Alexander Ach

, Journal of Macromolecular Science, Part A Pure and Applied Chemistry Volume 30, 1993 - Issue 9-10

For example, a cellulose acetate cup buried in sewage sludge lost more than 70% of its original weight within about 18 months. In an aqueous environment (Sturm's test), the decomposition amounted to more than 60%.

Aerobic biodegradation of cellulose acetate

Charles M. Buchanan, Robert M. Gardner, Ronald J. Komarek

, Journal of Applied Polymer Science, Volume47, Issue10 10 March 1993 Pages 1709-1719

Cellulose acetate (DS = 2.5) films required 10–12 days for extensive degradation. Films prepared from cellulose triacetate remained essentially unchanged after 28 days in the in vitro assay. The wastewater treatment assay was less active than the in vitro enrichment system.

Relevant Products

-

PVC

CAS:9002-86-2

-

K-CATALYST

CAS:1318-93-0

-

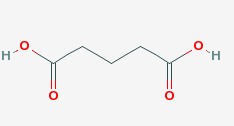

Oxalic Acid

CAS:68603-87-2